Infinity EDM & Machining

When your project is too large, too important, or too complex for the other guy, Infinity EDM & Machining delivers. Since 1998, we've provided the oversized and precision capacity, around-the-clock availability, and comprehensive manufacturing services that industry leaders depend on.

A never ending focus on excellence.

Our process knowledge and capabilities make your ideas a reality

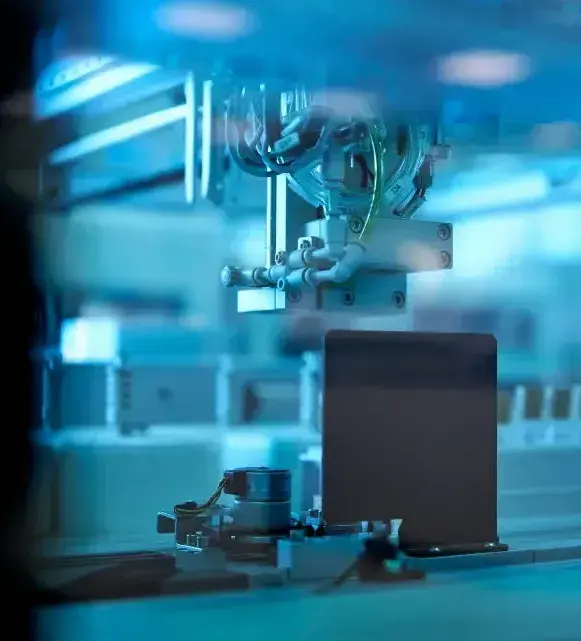

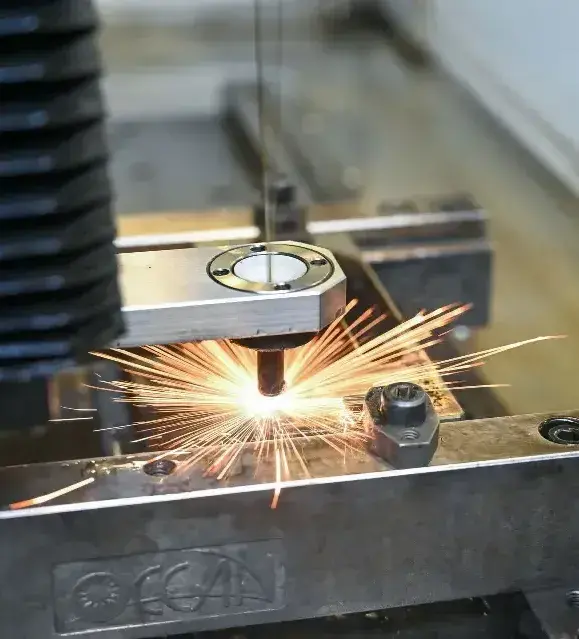

Electrical Discharge Machining (EDM)

Wire EDM removes material through electrical erosion using a continuously fed wire electrode. Perfect for cutting hardened dies, punch shapes, and complex contours in conductive materials.

Our oversized machines—including some of the largest in the world—handle work that exceeds most job shops' capacity.

CNC Machining

CNC machining uses computer-controlled multi-axis machines to remove material, creating precise features in a wide range of metals and alloys. Ideal for fixture building, hard milling, die sets, mold bases, and prototyping from single pieces to short production runs.

Our work centers handle oversized and standard components, with capabilities including 5-axis for complex geometries. We've built capabilities to deal with the most complex jobs.

Small Hole Drilling

EDM small hole drilling uses a rotating tubular electrode to burn precise holes through electrically conductive materials, regardless of hardness. Essential for creating starter holes for wire EDM, cooling channels in molds, and precision orifices in hardened components.

Our equipment handles a wide range of sizes and depths. We specialize in the difficult.

High-Capacity Grinding

Surface grinding uses precision abrasive wheels to achieve exceptional flatness and parallel surfaces on metal plates and components. Critical for die sets, mold bases, and any application requiring tight thickness tolerances and flat reference surfaces.

Our grinders handle oversize work pieces with sub-mill tolerances and flatness needs.

Learn more about our capabilities.

Infinity has a unique set of manufacturing tools and facilities designed to meet your needs.

We have the tools for your job:

Machine Capacities

Material Handling

Manufacturing Knowledge

Get SpecificsExperience with difficult materials makes Infinity special

Just a sample of the alloys we work with on a regular basis

Hardened Tool Steels

D2, H13, A2, S7, O1, M2

Nickel Superalloys

Inconel, Hastelloy, Waspaloy

Tungsten Carbide

Solid carbide tooling, inserts, composites

Titanium Alloys

Ti-6Al-4V, Ti-8Al-1Mo-1V, Ti-13V-11Cr-3Al

Cobalt Alloys

MP35N, Elgiloy, Stellite

High-Temperature Superalloys

Udimet, Rene 41, Astroloy

Why Choose Infinity?

1

Size

We handle the entire range, including the small and the absurdly large.

2

Material

Difficult to machine and hard to find is our day-to-day. Can't isn't a thing.

3

Precision

Our metrology is on target. We regularly meet sub-mill needs. Ask about our CMM.

4

Delivery

Meeting your commitments is critical. We're your partner in on-time performance.

Discover Infinity

A never ending focus on excellence.